In the fast-paced world of electronics, speed and precision are paramount. Whether you're a hobbyist working on a personal project or a company developing the next big thing, having access to fast turn custom PCB (Printed Circuit Board) parts can make all the difference. This article delves into the world of quick turn PCBs, exploring the processes, benefits, and services that ensure your projects stay on track.

Quick turn PCB prototypes are essential for testing and validating designs before full-scale production. They allow PCB designers to identify and rectify any potential issues, ensuring that the final product is both functional and reliable. With turnaround times as short as 24 hours, these prototypes enable rapid development cycles, helping you stay ahead of the competition.

When embarking on a new project, obtaining accurate PCB quotes is a crucial first step. These quotes provide a clear understanding of the costs involved, allowing for better budgeting and planning. Leading PCB manufacturing facilities offer comprehensive production services, from initial design consultation to final assembly. This ensures a seamless process, with all aspects of PCB fabrication and assembly handled under one roof.

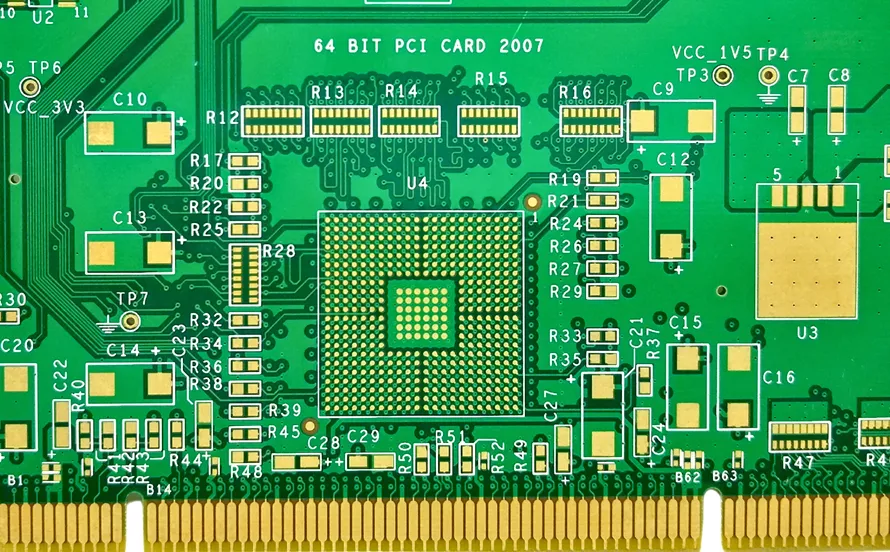

The journey of a printed circuit board begins with a Gerber file, a standard format for PCB design data. This file contains all the necessary information for manufacturing the board, including the layout, dimensions, and component placements. Once the Gerber file is received, the PCB fabrication process begins. This involves several steps, including:

Material Selection: Choosing the right materials, such as rigid or rigid flex, based on the project's requirements.

Layering: Creating the multiple layers of the PCB, which may involve both conductive and non-conductive materials.

Etching: Removing excess material to reveal the desired circuit patterns.

Drilling: Creating holes for components and vias.

Plating: Adding a conductive layer to the drilled holes.

Solder Mask Application: Applying a protective layer to prevent short circuits.

Silkscreen Printing: Adding labels and markings for easier assembly.

PCB assembly is the process of placing and soldering components onto the fabricated board. This step is crucial for ensuring that the PCB functions as intended. High-quality PCB assembly services focus on precision and reliability, using advanced equipment and techniques to achieve optimal results. The lead time for PCB assembly can vary based on the complexity of the design and the number of units required. However, many manufacturers offer expedited services to meet tight deadlines.

A reputable PCB manufacturing facility boasts extensive manufacturing capabilities, enabling them to handle a wide range of projects, from simple single-layer boards to complex multi-layer designs. These facilities are equipped with state-of-the-art machinery and staffed by experienced professionals who are committed to delivering high-quality products.

Customer service is another critical aspect of the PCB manufacturing process. From the initial PCB order to the final delivery, a dedicated customer service team ensures that all your questions and concerns are addressed promptly. This level of support helps build trust and confidence, making it easier to navigate the complexities of PCB production.

Quick turn printed circuit boards offer several advantages, including

Reduced Development Time: With turnaround times as short as 24 hours, quick turn PCBs accelerate the development process, allowing for faster iterations and quicker time-to-market.

Cost Savings: Rapid prototyping helps identify and fix issues early in the design process, reducing the risk of costly errors in full-scale production.

Flexibility: Quick turn services cater to both small and large orders, making them suitable for a wide range of projects.

High Quality: Despite the fast turnaround, reputable manufacturers maintain strict quality control standards, ensuring that each PCB meets the required specifications.

A1: A quick turn PCB is a printed circuit board that is manufactured and delivered in a significantly shorter time frame than standard PCBs. This service is ideal for rapid prototyping and urgent projects.

A2: Turnaround times for quick turn PCB prototypes can be as short as 24 hours, depending on the complexity of the design and the manufacturer's capabilities.

A3: To obtain an accurate PCB quote, you will need to provide detailed design files, typically in Gerber format, along with any specific requirements such as material type, layer count, and quantity.

A4: Rigid PCBs are made from solid, inflexible materials, while rigid flex PCBs combine rigid and flexible layers. Rigid flex PCBs offer greater design versatility and are often used in applications where space and weight are critical factors.

A5: Reputable manufacturers adhere to strict quality control standards, using advanced testing equipment and procedures to ensure that each PCB meets the required specifications. This includes visual inspections, electrical testing, and functional testing.

A6: Yes, quick turn PCB services cater to both small and large orders, making them suitable for a wide range of projects, from individual prototypes to full-scale production runs.

Fast turn custom PCB parts are a game-changer for the electronics industry, offering speed, quality, and convenience that can significantly enhance your project's success. By partnering with a reliable PCB manufacturing facility, you can benefit from comprehensive production services, high-quality fabrication and assembly, and exceptional customer service. Whether you need quick turn PCB prototypes or full-scale production, these services ensure that your printed circuit boards are delivered on time and to the highest standards.