Creating a custom circuit board (PCB) can be a highly rewarding process, whether you're a hobbyist, an engineer, or an entrepreneur. Custom circuit boards are the backbone of nearly all electronic devices, providing a platform to connect and control various components. In this article, we'll guide you through the steps to design and manufacture your own custom PCB, using straightforward language and practical tips.

A Printed Circuit Board (PCB) is a flat board made of non-conductive material that supports and connects electronic components using conductive pathways, tracks, or signal traces etched from copper sheets. PCBs are found in almost every electronic device, from simple gadgets to complex machinery.

Creating a custom PCB allows you to tailor the design to your specific needs, whether it's for a unique project or to improve the performance and reliability of an existing device. Custom circuit boards can also help reduce the size and complexity of your electronic projects.

Before you start designing your custom PCB, you need to have a clear understanding of your project's requirements. What components will you use? What is the board's size and shape? What are the power requirements? Answering these questions will help you create a design that meets your needs.

The first step in the actual design process is creating a schematic diagram. This diagram represents the electrical connections between the components. You can use software tools like KiCad, Eagle, or Altium Designer to create your schematic. Make sure to double-check your connections and component values to avoid mistakes later on.

Once your schematic is complete, the next step is to lay out the components on the PCB. Placement is crucial as it affects the board's performance and manufacturability. Place components logically, keeping related components close together and considering the flow of signals.

Routing involves creating the conductive pathways that connect the components. This can be done manually or using the auto-router feature in your design software. Pay attention to trace width, spacing, and the overall layout to ensure reliable connections and signal integrity.

Before sending your design to a PCB manufacturer, run a Design Rule Check (DRC) to ensure that your layout meets the manufacturing requirements. This check will help identify any issues that could cause problems during production.

Gerber files are the standard format used by PCB manufacturers to produce your custom circuit board. These files contain all the information needed to create your PCB, including the layout, drill holes, and silkscreen. Your design software will have an option to export your design as Gerber files.

Selecting a reliable PCB manufacturer is crucial for the success of your project. Look for a manufacturer with experience in custom circuit boards and a good reputation for quality and customer service. Some popular options include JLCPCB, PCBWay, and Advanced Circuits.

Once you've chosen a manufacturer, upload your Gerber files to their website and specify your board's requirements, such as the number of layers, material, thickness, and finish. Review the manufacturer's guidelines to ensure your design meets their specifications. After placing your order, the manufacturer will produce your custom PCB and ship it to you.

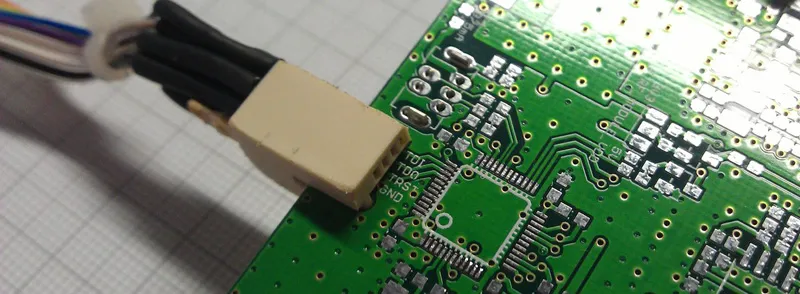

When you receive your custom PCB, the next step is to assemble the components. This involves soldering the components onto the board. You can do this manually using a soldering iron or use a reflow oven for surface-mount components. Make sure to follow proper soldering techniques to ensure reliable connections.

After assembling your PCB, it's essential to test it to ensure it works as intended. Use a multimeter to check for continuity and correct voltage levels. Power up your board and verify that all components function correctly. If you encounter any issues, troubleshoot by checking your schematic and layout for errors.

When designing your custom PCB, simplicity is key. Avoid overly complex designs that can be difficult to manufacture and troubleshoot. Focus on creating a clean and efficient layout that meets your project's requirements.

Utilize PCB design software to streamline the design process and ensure accuracy. These tools offer features like auto-routing, design rule checks, and 3D visualization, making it easier to create a professional-quality PCB.

Adhere to design guidelines provided by your PCB manufacturer. These guidelines will help you create a design that is manufacturable and meets industry standards. Pay attention to trace width, spacing, and other critical parameters.

Before sending your design to the manufacturer, thoroughly review your schematic and layout. Run design rule checks and verify that all connections are correct. This will help prevent costly mistakes and ensure a successful outcome.

Creating a custom circuit board is a rewarding process that allows you to bring your electronic projects to life. By following the steps outlined in this article, you can design and manufacture a custom PCB that meets your specific needs. Remember to plan carefully, use design software, and choose a reliable PCB manufacturer to ensure the best results.

A PCB manufacturer is a company that produces printed circuit boards based on the design files provided by customers. They use specialized equipment and processes to create high-quality PCBs for various applications.

Gerber files are the standard format used by PCB manufacturers to produce printed circuit boards. These files contain all the information needed to create the PCB, including the layout, drill holes, and silkscreen.

When choosing a PCB manufacturer, look for a company with experience in custom circuit boards, a good reputation for quality, and excellent customer service. Consider factors like pricing, lead times, and available services.

A Design Rule Check (DRC) is a process that verifies your PCB layout against the manufacturing requirements. It helps identify any issues that could cause problems during production, ensuring that your design is manufacturable.

Routing is important because it creates the conductive pathways that connect the components on the PCB. Proper routing ensures reliable connections, signal integrity, and optimal performance of the circuit.

Custom circuit boards offer several benefits, including tailored designs that meet specific project requirements, improved performance and reliability, and reduced size and complexity of electronic projects.