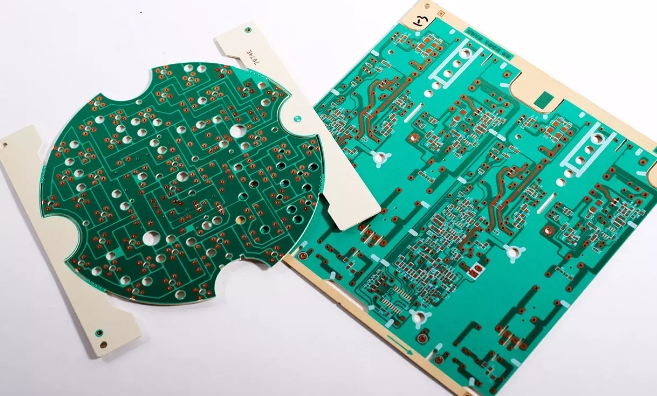

Copper clad laminate (CCL) is a fundamental material in the manufacturing of printed circuit boards (PCBs). It forms the backbone of the PCB, providing the necessary structural support and electrical pathways for electronic components. In this article, we will explore the various aspects of copper clad laminate, including its composition, types, and applications. We will also discuss how it impacts the performance of PCBs in different industries.

Copper clad laminate is a composite material made by laminating a thin layer of copper foil onto a substrate or base material. This base material can be made from various materials, including paper, glass fiber cloth, and epoxy resin. The resulting laminate provides the structural integrity and electrical conductivity required for PCB manufacturing.

The base material is the foundation of the copper clad laminate. It can be made from different materials depending on the desired properties of the final PCB. Common base materials include:

Paper Base: Used for low-cost, low-performance applications.

Glass Fiber Cloth Base: Provides high strength and stability, suitable for high-performance applications.

Epoxy Resin: Offers good mechanical and electrical properties, widely used in various applications.

The copper foil is the conductive layer in the copper clad laminate. It forms the electrical pathways on the PCB. The thickness of the copper foil can vary depending on the requirements of the PCB design.

Reinforcing materials, such as glass fiber cloth, are used to enhance the mechanical strength and stability of the laminate. They help to prevent warping and deformation during the manufacturing process.

Insulation resin, such as epoxy resin, is used to bind the base material and copper foil together. It also provides electrical insulation and protects the copper foil from oxidation and corrosion.

Copper clad laminates can be classified based on their base materials and applications:

Paper-based CCLs are made from paper impregnated with phenolic resin. They are cost-effective and suitable for low-frequency, low-speed applications. However, they have limited mechanical strength and are not suitable for high-performance applications.

Glass fiber cloth-based CCLs are made from woven glass fiber cloth impregnated with epoxy resin. They offer high mechanical strength, stability, and excellent electric performance. These laminates are suitable for high-speed, high-frequency applications and are widely used in the aerospace and defense industries.

Epoxy resin-based CCLs are made from epoxy resin reinforced with glass fiber or other materials. They provide a good balance of mechanical and electrical properties and are used in a wide range of applications, from consumer electronics to industrial equipment.

Copper clad laminates designed for high-speed and high-frequency applications must have low dielectric loss and excellent electric performance. This ensures that signals can travel quickly and accurately through the PCB without significant degradation.

Dielectric loss measures the energy lost as heat in the insulating material of the laminate. Low dielectric loss is essential for high-frequency applications to minimize signal loss and maintain signal integrity.

The electric performance of the copper clad laminate is determined by its dielectric constant, dielectric loss, and insulation resistance. High electric performance is crucial for applications requiring precise and reliable signal transmission.

Mechanical strength is vital for the durability and longevity of the PCB. Reinforcing materials, such as glass fiber cloth, enhance the mechanical strength and stability of the laminate, making it suitable for demanding applications.

Copper clad laminates are used in a wide range of applications, from consumer electronics to aerospace and defense. Some common applications include:

Copper clad laminates are used in the manufacturing of PCBs for consumer electronics, such as smartphones, tablets, and laptops. They provide the necessary electrical pathways and structural support for the electronic components.

In industrial equipment, copper clad laminates are used to create PCBs that control and monitor various processes. The high mechanical strength and electric performance of glass fiber cloth-based laminates make them suitable for these demanding applications.

In the aerospace and defense industries, copper clad laminates are used to create PCBs for critical applications, such as avionics and radar systems. The high-speed, high-frequency capabilities of these laminates ensure reliable and accurate signal transmission in these demanding environments.

Copper clad laminates are used in the manufacturing of PCBs for telecommunications equipment, such as routers, switches, and base stations. The low dielectric loss and high electric performance of these laminates ensure efficient and reliable signal transmission.

The copper foil in copper clad laminate forms the conductive layer that creates the electrical pathways on the PCB. It is essential for the transmission of electrical signals between the electronic components.

The base material determines the mechanical strength, stability, and electrical properties of the copper clad laminate. Different base materials, such as paper, glass fiber cloth, and epoxy resin, provide varying levels of performance and suitability for different applications.

Dielectric loss measures the energy lost as heat in the insulating material of the laminate. Low dielectric loss is crucial for high-frequency applications to minimize signal loss and maintain signal integrity.

Glass fiber cloth-based laminates offer high mechanical strength, stability, and excellent electric performance. These properties make them suitable for high-speed, high-frequency applications, such as those in the aerospace and defense industries.

Reinforcing materials, such as glass fiber cloth, enhance the mechanical strength and stability of the laminate. They help to prevent warping and deformation during the manufacturing process, ensuring the durability and longevity of the PCB.

Copper clad laminates are used in a wide range of applications, including consumer electronics, industrial equipment, aerospace and defense, and telecommunications. They provide the necessary structural support and electrical pathways for electronic components in these industries.

Copper clad laminate is a crucial material in the manufacturing of printed circuit boards. Its composition, including the base material, copper foil, reinforcing material, and insulation resin, determines the mechanical and electrical properties of the final PCB. By understanding the different types of copper clad laminates and their applications, manufacturers can choose the right material for their specific needs. Whether it's for consumer electronics, industrial equipment, or aerospace and defense, copper clad laminates play a vital role in ensuring the performance and reliability of PCBs.