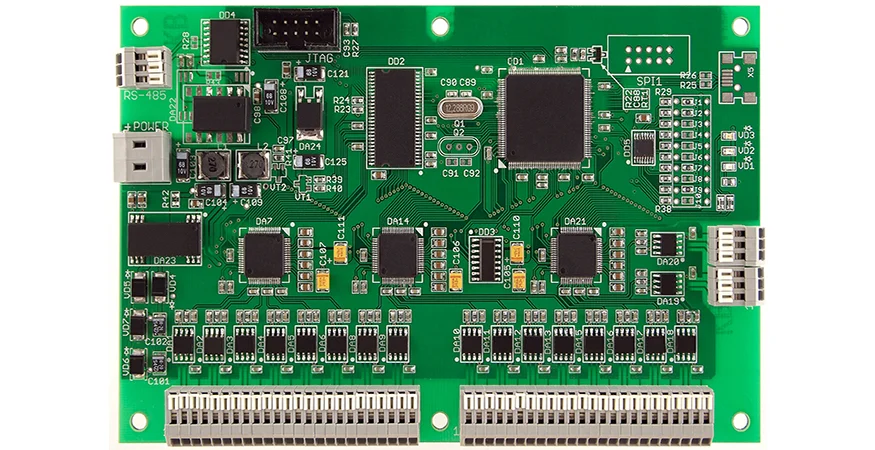

Printed circuit boards (PCBs) are the backbone of modern electronics. From smartphones to satellites, these sophisticated components play a critical role in making devices work. When designing a custom PCB for your project, understanding how to estimate custom PCB cost per unit is crucial. In this guide, we'll explore the factors that influence the price of a custom PCB and provide you with a step-by-step approach to calculating its cost effectively.

Before diving into the specifics of cost estimation, it's important to have a basic understanding of what goes into creating a custom circuit board. PCBs come in various sizes and complexities, from simple single-layer boards to complex multilayer boards. The manufacturing process involves etching conductive pathways on a non-conductive substrate, which can be made of materials like fiberglass or ceramic.

Factors Influencing PCB Cost

Board Size: The larger the board, the higher the material and manufacturing costs.

Number of Layers: More layers mean increased complexity and higher costs.

Material Type: Different substrates and metals used can affect the final cost.

Complexity of Design: Fine pitch components and tight tolerances increase costs.

Quantity: Larger orders often benefit from volume discounts.

Start by defining the essential specifications of your PCB. This includes the board size, number of layers, and any specific material requirements. For instance, a standard FR-4 substrate is commonly used for general-purpose applications due to its balance between performance and cost.

Many PCB manufacturers offer online cost estimators on their websites. These tools allow you to input your board specifications and receive an approximate cost estimate. While they may not be entirely accurate, they provide a good starting point for budgeting.

Here’s an example of how you might use an online cost estimator:

Board Size: Enter the dimensions of your PCB, such as 5 inches by 3 inches.

Number of Layers: Select the number of layers required, such as 2-layer for simple designs.

Quantity: Input the number of boards you plan to order, which can significantly impact the per-unit cost.

Some features can add to the overall cost. These include:

Surface Finish: Options like HASL (Hot Air Solder Leveling) are more affordable, while ENIG (Electroless Nickel Immersion Gold) is pricier but offers better performance.

Silk Screen and Legend: Adding text and symbols to the board can help with assembly and debugging but adds to the cost.

Drilling Requirements: Special drilling needs, such as blind or buried vias, can increase manufacturing costs.

Don't forget to account for shipping and handling fees when calculating the total cost. Some manufacturers offer free shipping for bulk orders, while others charge based on weight and distance.

To ensure you're getting the best deal, request quotes from at least three different PCB manufacturers. Compare their pricing, lead times, and quality guarantees. This step is crucial for obtaining an accurate cost estimate and identifying potential savings.

Yes, typically, the cost per unit decreases as the order quantity increases due to economies of scale.

Opt for standard materials and processes, avoid unnecessary features, and consider a simpler design where possible.

Complex designs may require specialized processes and materials, which can increase costs. Work closely with your manufacturer to optimize the design for manufacturabilit

Be sure to inquire about setup fees, tooling charges, and any additional services like testing or certification.

Calculating the cost of a custom PCB requires careful consideration of multiple factors. By following the steps outlined in this guide, you can make informed decisions that align with your budget and project requirements. Remember, while cost is an important factor, ensuring that your PCB meets all necessary performance standards is equally crucial. Happy designing!

This comprehensive guide provides a detailed breakdown of the factors involved in PCB cost calculation, along with practical tips and advice. Whether you're a seasoned engineer or just starting out, understanding these aspects will help you manage your budget effectively and produce high-quality circuit boards.