When discussing circuit boards, one often encounters references to voltage ratings, particularly the term "220V." This designation is crucial for understanding the operational parameters of various electrical devices and systems. This article delves into the significance of 220V circuit boards, their applications, benefits, and considerations for users and manufacturers alike.

A 220V circuit board is designed to handle an operating voltage of 220 volts, commonly used in many countries around the world. These boards are integral components of electrical systems, serving as the foundation for various devices, from household appliances to industrial machinery. The design and construction of 220V circuit boards must comply with specific safety standards to ensure reliable operation and user safety.

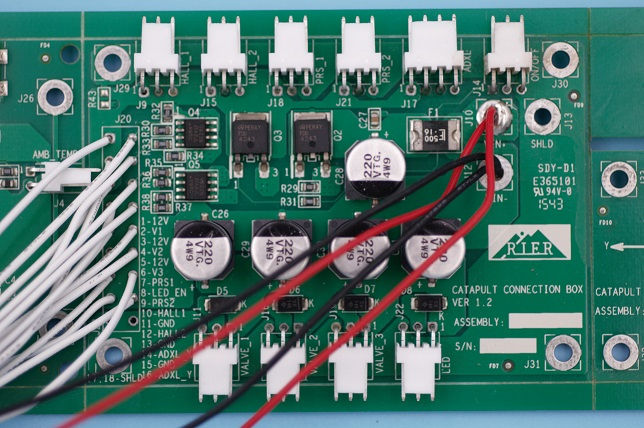

Power Supply Modules: These are responsible for converting and regulating incoming voltage to appropriate levels for the components on the board.

Resistors and Capacitors: Essential for managing electrical signals and ensuring stability within the circuit. They help prevent voltage spikes that could damage sensitive components.

Transistors: Act as switches or amplifiers, controlling the flow of electricity through the circuit board.

Connectors and Terminals: Facilitate easy connections between the circuit board and other components or external devices, ensuring a secure and efficient electrical pathway.

Microcontrollers: Often found in advanced 220V circuit boards, microcontrollers manage various functions, allowing for programmability and enhanced functionality.

Home Appliances: Many household devices, such as refrigerators, washing machines, and air conditioners, rely on 220V circuit boards to operate efficiently and safely.

Industrial Equipment: Machinery used in manufacturing and processing often employs 220V circuit boards, enabling precise control and automation of production processes.

Lighting Systems: Street lights and industrial lighting solutions frequently utilize 220V boards to manage high-voltage operations without compromising safety.

HVAC Systems: Heating, ventilation, and air conditioning systems often incorporate 220V circuit boards to ensure efficient climate control in residential and commercial settings.

Efficiency: Operating at 220V allows for lower current levels compared to lower voltage systems, which can result in reduced energy losses and improved overall efficiency.

Power Handling: These boards can handle higher power loads, making them suitable for a wide range of applications without the risk of overheating or failure.

Reduced Wire Size: Because higher voltage systems can operate with lower current, the wiring required can be smaller in gauge, leading to easier installation and potentially lower material costs.

Global Compatibility: Many regions, particularly in Europe and Asia, use 220V as standard voltage, making these circuit boards universally applicable in those markets.

Safety Standards: It’s imperative to adhere to local and international safety regulations when designing and manufacturing 220V circuit boards. This includes proper insulation, grounding, and protection mechanisms.

Thermal Management: High voltages can generate significant heat. Adequate thermal management solutions, such as heat sinks or cooling fans, should be incorporated to maintain optimal operating temperatures.

Component Selection: Choosing components rated for 220V operation is crucial. Overrated components can lead to inefficiencies and potential safety hazards.

Testing and Quality Control: Rigorous testing protocols must be established to ensure reliability and safety. This includes functional testing, stress testing, and compliance with safety standards.

Users have expressed a variety of opinions regarding 220V circuit boards. Many appreciate the efficiency and reliability of appliances that utilize these boards, noting significant performance improvements over lower voltage alternatives. Industrial users often highlight the robustness and power handling capabilities of 220V boards, especially in demanding applications. However, concerns regarding safety and maintenance were also mentioned, emphasizing the importance of proper installation and adherence to safety standards.

220V circuit boards play a vital role in the functionality and efficiency of various electrical devices and systems. Understanding their design, applications, and the considerations necessary for safe operation is crucial for manufacturers and users alike. By leveraging the advantages of 220V technology while adhering to safety regulations, users can ensure optimal performance and reliability in their electrical systems.

1. What is the difference between 220V and 110V circuit boards?

The primary difference lies in their voltage levels. 220V systems typically handle higher power loads and can be more efficient due to lower current levels, while 110V systems are commonly used in North America and are often deemed safer for residential use.

2.Are 220V circuit boards suitable for all types of devices?

While many appliances and industrial equipment are designed for 220V operation, it’s essential to ensure compatibility with the device's specifications. Always consult the manufacturer’s guidelines before use.

3. What safety measures should be taken when working with 220V circuit boards?

Ensure proper insulation, grounding, and use of safety-rated components. Always follow local electrical codes and standards to minimize risks associated with high-voltage systems.

4. Can I convert a 110V device to work with a 220V circuit board?

Converting a 110V device to 220V typically requires a transformer or a power supply designed for dual voltage. It is important to consult an electrical professional for modifications to avoid damage or hazards.