Printed Circuit Boards (PCBs) are at the heart of nearly all modern electronic devices, acting as the backbone that connects and supports various electronic components. The design and structure of a PCB are crucial to its functionality, and one of the key elements in this design is the layers of the PCB. A well-designed PCB is often made up of multiple layers, each serving a distinct purpose to ensure optimal performance and reliability of the final electronic device. In this article, we will explore the various layers in printed circuit boards (PCBs), from copper traces to solder masks, and discuss how these layers work together in the manufacturing process.

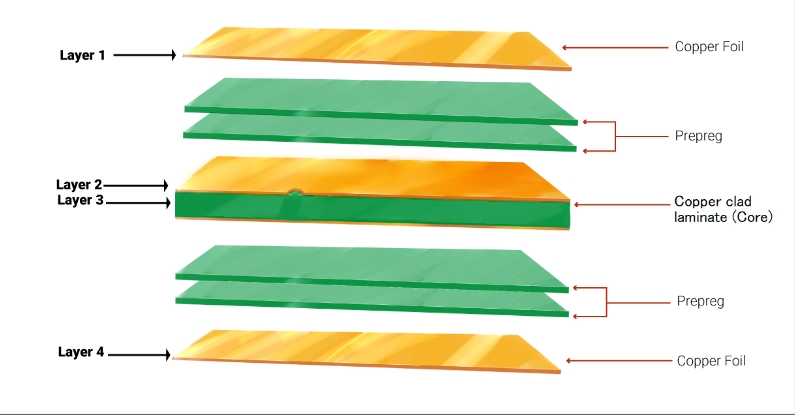

A printed circuit board consists of several layers of conductive and non-conductive materials, which are essential for creating electrical pathways and supporting the electronic components that make up the circuit. The layers in a PCB typically include:

Top and Bottom Layers: These are the external layers of the PCB, typically made from copper foil, where the copper traces are etched to create the conductive pathways for electrical signals. The top and bottom layers are exposed and can be used for surface-mount components or connectors.

Internal Layers: In multi-layer PCBs, there are additional internal layers that help with routing signals and distributing power. These layers are separated by insulating materials and are typically used in complex designs that require more connections than a simple two-layer board can provide. Internal layers may include power planes (used to distribute power) and signal layers that handle the routing of data signals.

Power Plane: The power plane is a dedicated internal layer used to deliver stable power to various parts of the circuit. It is typically a copper pour that covers large areas of the PCB to ensure even distribution of power, reducing noise and voltage fluctuations.

Conductive Layers: Copper traces are used in the conductive layers to form the electrical paths between components. These traces are carefully etched during the manufacturing process to create the specific connections dictated by the PCB design.

Solder Masks: The solder mask layer is applied over the copper traces and serves as an insulating barrier to prevent accidental short circuits during soldering. This layer also provides protection against environmental damage. It is often green, although it can be found in other colors like red, blue, or black.

Silkscreen Layer: The silkscreen layer is used to print labels, component identifiers, and other markings on the PCB. This layer helps with the PCB manufacturing process by ensuring that components are placed correctly during assembly.

The layers of the PCB are carefully designed and manufactured to serve distinct functions, and each layer plays a significant role in the overall performance of the circuit:

Top and Bottom Layers: The external layers provide the primary surface for component placement and electrical routing. Components such as capacitors, resistors, and ICs are often soldered to the top and bottom layers, where copper traces connect them to form the complete circuit. These layers can also be used for copper pours, which help to ground the circuit or provide a consistent power supply.

Internal Layers: In layered PCBs with more than two layers, the internal layers provide additional pathways for routing signals and power. These layers are particularly important for high-density PCB designs that require a greater number of connections in a compact space. Internal layers also contribute to the overall electrical performance by minimizing signal interference and crosstalk.

Copper Pour: A copper pour is an area on the PCB where copper is applied to create a continuous copper surface. This is often used to form the power plane or to establish a solid ground connection. Copper pours are vital for ensuring stable power distribution and minimizing electrical noise.

Solder Masks: The solder mask layer is an essential part of PCB construction, as it prevents the accidental soldering of unwanted areas. The solder mask also protects the board from environmental damage, ensuring that the electronic components are safely mounted without the risk of contamination.

Silkscreen Layer: The silkscreen is a printed layer that provides essential markings for PCB assembly. It includes information such as component labels, logos, and identifiers for vias and other features. This layer ensures that components are placed accurately and that the assembly process runs smoothly.

The process of designing and manufacturing printed circuit boards (PCBs) is highly complex and requires careful planning. The PCB design phase begins with schematic capture, where the connections between electronic components are determined. This is followed by layout design, where the actual physical layout of the copper traces and other components is planned.

Once the design is complete, the PCB manufacturing process begins. The layers are fabricated separately, and copper foil is laminated onto the board. For multi-layer boards, the internal layers are sandwiched together with insulating layers. The board is then subjected to a series of processes such as drilling, etching, and applying solder masks and silkscreen layers. Finally, the board is tested for continuity, ensuring that all the copper traces and conductive layers are functioning properly.

Multi-layer PCBs offer several advantages over traditional single-layer or double-layer boards, especially when designing high-performance electronic devices. Some of the key benefits include:

Increased Component Density: Multi-layer PCBs allow for more components to be placed in a smaller area, making them ideal for modern electronic products that require compact designs.

Improved Signal Integrity: With the inclusion of internal layers and power planes, multi-layer boards can reduce the risk of signal interference, ensuring the proper functioning of sensitive circuits.

Better Power Distribution: The inclusion of dedicated power planes in multi-layer designs helps to evenly distribute power across the board, improving the overall efficiency and stability of the device.

Enhanced Performance: By providing more routing layers, multi-layer PCBs enable faster signal transmission and reduce the chances of electrical noise or signal degradation, which is crucial for high-speed and high-performance devices.

The layers of the PCB are fundamental to its design and functionality. From the top and bottom layers that house the copper traces to the internal layers that facilitate signal routing and power distribution, each layer serves a crucial role in ensuring that the printed circuit board performs as intended. Whether in single-sided PCBs or complex multi-layer PCBs, the layers are carefully designed and manufactured to support the various electronic components that make up the electronic circuit.

1. What is the difference between single-layer and multi-layer PCBs?

Single-layer PCBs have only one layer of copper traces, while multi-layer PCBs include multiple conductive layers, allowing for more complex circuits and more components to be integrated into a smaller space.

2. What are the benefits of having multiple layers in a PCB?

Multi-layer PCBs offer better signal integrity, more efficient power distribution, reduced interference, and allow for a higher component density, making them ideal for compact and high-performance electronic devices.

3. What is a copper pour in PCB design?

A copper pour is a large area of copper that covers part of the PCB to create a power plane or a ground connection. It helps to ensure stable power distribution and reduces electrical noise.

4. What materials are used for the layers in a PCB?

The layers of a PCB are typically made from copper foil (for conductive layers), fiberglass or resin (for the substrate), and solder masks or silkscreen for protective and labeling purposes.

5. Why is signal integrity important in PCB design?

Signal integrity ensures that signals are transmitted accurately without interference or loss of quality. This is especially important for high-speed or high-frequency circuits found in devices like smartphones, computers, and medical equipment.