Solder paste printing is a critical process in modern electronics manufacturing, particularly in surface mount technology (SMT). The quality of solder paste printing has a direct impact on the reliability of solder joints and the overall assembly of printed circuit boards (PCBs). This article provides a comprehensive overview of solder paste printing, covering its fundamental principles, the role of printing machines, stencil printing techniques, the printing process, and essential considerations for quality control. We’ll also include a few FAQs to address common questions related to solder paste printing.

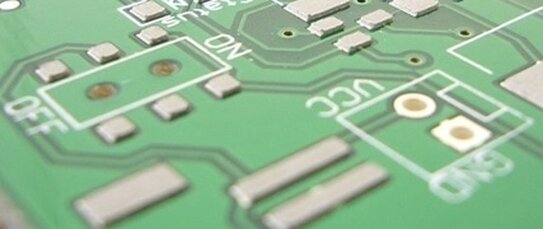

Solder paste printing is the process of depositing a mixture of solder and flux (known as solder paste) onto specific areas of a PCB using a stencil. These areas are typically pads where electronic components will be mounted. Proper solder paste application is crucial because it ensures secure, conductive solder joints that hold the components in place and provide electrical connections between them.

Printing Machines

The solder paste printing process requires specialized printing machines to ensure accurate and consistent application. These machines use precise control systems to apply solder paste with high accuracy, adjusting parameters like pressure, speed, and alignment. Most modern machines include features such as vision systems for alignment correction, squeegee control, and automated cleaning cycles, which help maintain accuracy during high-speed production.

Stencil Printing

Stencil printing is a core part of the solder paste printing process. A thin metal or plastic stencil, typically laser-cut, is placed over the PCB, and solder paste is applied across it with a squeegee. The stencil openings align with the pads on the PCB, allowing the paste to deposit only on the desired areas. The stencil thickness, aperture shape, and material impact the volume and precision of the solder paste deposits, influencing the quality of the final solder joints.

Solder Joint Quality

Solder joints form when the applied solder paste is heated in a reflow oven, melting and bonding electronic components to the PCB. High-quality solder joints ensure electrical connectivity and mechanical strength, essential for reliable device function. Defects in the solder joints, such as insufficient solder or misalignment, can lead to weak connections and malfunctioning circuits, which is why precise paste application is crucial.

Printing Process Steps

Preparation: The PCB and stencil are aligned within the printing machine. Printing parameters, such as speed, pressure, and angle of the squeegee, are set based on the specific requirements of the PCB and paste.

Paste Application: Solder paste is applied to the stencil, and a squeegee moves across the stencil surface, forcing the paste through the openings and onto the PCB pads.

Inspection: After printing, the paste deposits are checked, typically using Automated Optical Inspection (AOI) or 3D inspection systems, to ensure the correct volume and placement of solder paste. Any inconsistencies can be identified and corrected before the reflow process.

Several factors can impact the quality of solder paste printing, including:

Stencil Design: The size, shape, and thickness of the stencil apertures should be tailored to the PCB layout and the specific components to be soldered.

Paste Composition: The composition and viscosity of the solder paste influence its flow and spread during printing.

Printing Parameters: Squeegee speed, pressure, and angle need to be carefully controlled to ensure uniform paste deposition.

Environmental Conditions: Temperature and humidity affect solder paste properties, so maintaining consistent environmental conditions is essential.

Modern printing machines offer several advanced features to enhance process reliability:

Automated Optical Inspection (AOI): High-resolution cameras capture detailed images of the printed solder paste, allowing automated quality checks on every board.

Stencil Cleaning Systems: Built-in cleaning systems can clear excess solder paste and other contaminants, ensuring optimal stencil performance.

Closed-loop Feedback Systems: These systems adjust parameters in real-time based on inspection results, helping to maintain consistent paste volume and placement throughout a production run.

What types of defects can occur in solder paste printing?

Common defects include insufficient or excessive solder paste deposition, misalignment, bridging (where paste connects adjacent pads), and voids within the paste. These can lead to poor solder joints, affecting device reliability.

How often should the stencil be cleaned during the printing process?

The frequency of stencil cleaning depends on the type of paste and the specific requirements of the production line. Many printing machines include automatic cleaning cycles that can be set to run periodically to prevent paste buildup and ensure consistent print quality.

What is the role of environmental control in solder paste printing?

Environmental factors such as temperature and humidity can affect the properties of the solder paste, such as viscosity and drying rate. Controlled conditions help maintain consistency, reducing the risk of defects.

How does stencil thickness impact solder paste printing?

Stencil thickness affects the volume of solder paste deposited on the pads. Thicker stencils allow more paste deposition, suitable for larger components, while thinner stencils are better for fine-pitch components where precise paste volumes are required.

Can solder paste printing be used for high-density PCBs?

Yes, but it requires advanced stencils and precise printing machines to handle the finer pitch and smaller components on high-density PCBs. Laser-cut stencils and 3D inspection systems are often used to meet these demands.

Solder paste printing is a foundational step in PCB assembly, impacting the quality of every solder joint and, ultimately, the reliability of electronic devices. By understanding the essentials of stencil design, printing machine functionality, and quality control, manufacturers can achieve consistent, high-quality solder paste printing results. With modern printing machines and meticulous process control, solder paste printing can support the demands of today’s high-density, high-performance electronic assemblies.