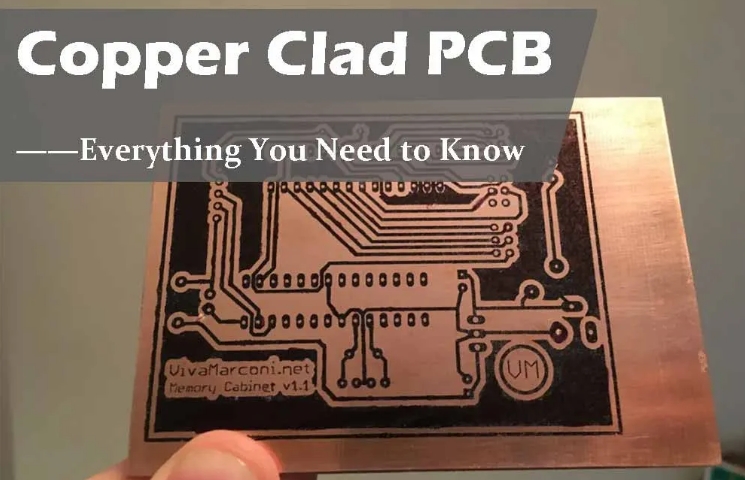

A copper clad board is an essential material in the manufacturing of printed circuit boards (PCBs), providing the foundation upon which electronic circuits are built. The board consists of a non-conductive substrate, typically made of glass fiber, to which a thin layer of copper foil is bonded. This combination of materials allows the board to deliver the necessary electrical conductivity and mechanical support for a variety of electronic devices. The copper clad laminate (CCL) created by bonding copper foil to the substrate is used as the core material for PCB production. Understanding the key features of copper clad boards, including the composition, production process, and applications, is crucial for selecting the right materials for specific electronic needs.

Glass Fiber:The glass fiber substrate is one of the most commonly used materials for copper clad boards due to its excellent properties. It provides strength, stability, and durability while also maintaining low thermal expansion. This makes it an ideal choice for the base material of the copper clad board. The glass fiber is typically woven into a fabric and then impregnated with resin to create a solid and reliable substrate that can withstand varying levels of stress and temperature changes.

Reinforcing Material:In some cases, additional reinforcing material is added to the glass fiber to further enhance the board’s mechanical properties. These materials might include aramid fibers, woven cloth, or other polymer composites that provide extra rigidity and support. Reinforced copper clad boards are particularly useful in applications where high mechanical stress is anticipated or where additional strength is needed for durability in harsh environments, such as in automotive, aerospace, or industrial electronics.

Copper Foil:The copper foil applied to the surface of the substrate is the most critical part of the copper clad board, as it provides the necessary electrical conductivity. The copper foil is bonded to the glass fiber substrate using a resin, and its thickness can vary depending on the application. Typically, copper foils range from 1 oz/ft² to 3 oz/ft², with higher thicknesses used for high-power applications. The thickness of the copper foil influences the board's performance, including signal integrity, heat dissipation, and power handling capabilities.

Copper Clad Laminate (CCL):The combination of glass fiber and copper foil forms the copper clad laminate (CCL), the finished product used to create printed circuit boards. The CCL can be manufactured with various types of resin systems, such as epoxy, phenolic, or polyimide, depending on the intended application. Each resin system offers different characteristics, such as improved thermal resistance or chemical stability. For example, polyimide laminates are often used for high-temperature applications, while epoxy-based laminates are more commonly found in consumer electronics.

Copper clad boards are used in a wide range of electronic applications. Their primary use is in the creation of PCBs, which are found in almost every electronic device, from consumer gadgets like smartphones and computers to industrial machinery and automotive systems. The combination of glass fiber and copper foil makes the material suitable for both low and high-frequency applications, including:

Consumer Electronics:In devices like smartphones, tablets, and laptops, copper clad boards provide the essential support for the microcircuits that enable the devices to function. The high-speed performance of these devices requires PCBs that can handle precise signal routing and efficient heat dissipation, which is achieved by using high-quality copper foil and glass fiber substrates.

Industrial Electronics:For industrial machinery, copper clad boards must be able to withstand higher mechanical stress and heat. The use of reinforcing materials and copper clad laminates designed for higher temperatures makes these boards ideal for industrial applications, such as power control systems, automation devices, and motor control circuits.

Automotive Electronics:The automotive industry uses copper clad boards for the production of electronic components that manage power distribution, navigation systems, and sensor technologies. These PCBs need to be highly reliable and durable, often requiring reinforced glass fiber for added strength and the ability to endure harsh conditions such as temperature fluctuations and vibrations.

Telecommunications:In telecommunications, copper clad boards are used to build the complex circuit boards that manage signal routing and data transmission. The use of copper foil ensures that the electrical signals are transmitted with minimal loss and high efficiency, which is critical in high-speed communication systems.

When selecting copper clad boards, it’s important to understand that one size does not fit all. Customization of the glass fiber substrate, copper foil thickness, and reinforcing material may be necessary depending on the specific requirements of the electronic device. Reliable technical support and custom solutions can help businesses tailor their copper clad laminates to meet the needs of unique applications.

Material Customization:Copper clad boards can be customized in terms of material type, thickness, and resin system. For example, if a PCB needs to handle higher temperatures, polyimide-based laminates may be used in place of standard epoxy laminates. Likewise, for high-speed circuits, copper foil thickness may need to be adjusted to ensure optimal performance.

Design Assistance:Many manufacturers of copper clad boards offer design assistance to ensure that the copper clad laminate meets the electrical and thermal performance requirements of the final product. This includes optimizing the layout for signal routing, minimizing impedance mismatches, and ensuring that the copper foil thickness is appropriate for power delivery.

Prototyping and Small-Scale Production:Prototyping is an essential step in developing a new product that relies on copper clad boards. Manufacturers often provide prototyping services to test the design before full-scale production begins. This allows engineers to verify the PCB’s performance under real-world conditions and make any necessary adjustments.

The cost of copper clad boards can vary depending on the materials, thickness, and customization options chosen. Typically, copper clad laminates made from standard glass fiber and copper foil may range in price from $5 to $50 per square meter. However, specialized laminates and custom solutions may cost more, with prices reaching upwards of $100 per square meter for high-performance boards used in industries like aerospace or telecommunications.

When comparing prices, it’s important to consider the following factors:

Material Quality: Higher-quality glass fiber and copper foil may increase the cost but will result in better performance and reliability.

Customization: Custom copper foil thicknesses, specialized resin systems, and reinforcing materials can drive up costs.

Volume: Bulk orders often lead to price reductions, so it’s worth considering long-term supply agreements for large-scale production.

Copper clad boards are a fundamental component in the manufacturing of printed circuit boards, providing the necessary electrical conductivity and mechanical support for a wide range of electronic applications. By understanding the key materials involved—glass fiber, reinforcing materials, copper foil, and copper clad laminates—businesses can make informed decisions when selecting the right copper clad boards for their needs. Whether you require a standard material or a custom solution, choosing a reliable supplier with expertise in copper clad laminates will ensure that your electronic products meet the required performance standards. With the right materials, support, and pricing, copper clad boards will continue to play a critical role in the development of the electronics of tomorrow.