A 2-layer printed circuit board (PCB) is a widely used type of PCB that features two conductive layers. These boards are integral to the functioning of many modern electronic devices, from smartphones to household appliances. In this article, we’ll explore everything you need to know about 2-layer PCBs, including the top and bottom layers, production process, types, and their various applications.

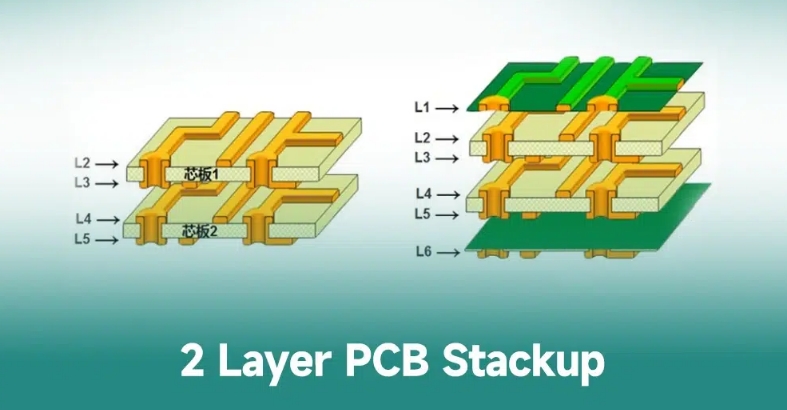

A printed circuit board (PCB) is a crucial component in the electronics industry, providing mechanical support and electrical connections between different components. It consists of several layers, each serving a specific purpose, depending on the type of PCB. 2-layer PCBs are among the simplest and most cost-effective designs, featuring a top layer and a bottom layer, with a layer of copper between them.

In a 2-layer PCB, the top layer refers to the side where most of the components are placed, while the bottom layer usually contains fewer components but still plays a critical role in routing signals. These two layers are connected through vias or drill holes, which allow electrical signals to pass from one side to the other.

The top and bottom layers are typically made of copper foil, which is etched to form the electrical paths or traces. The copper on these layers is crucial because it conducts electricity, forming the necessary connections between the components of the PCB.

The copper foil on the top layer and bottom layer is a thin sheet of copper material, usually around 1 to 3 mils thick. This copper layer is laminated onto the PCB substrate during the manufacturing process. After the copper is applied, it undergoes an etching process that removes unwanted copper and leaves behind the intricate network of traces that will serve as the electrical connections for the components.

For 2-layer PCBs, the layer of copper is typically thinner than that of multi-layer boards, making them more affordable while still capable of handling many electronic applications.

The production of 2-layer PCBs involves several steps to ensure proper functionality and high-quality performance. Below is a breakdown of the general production process:

Raw Material Preparation

The first step in the manufacturing of 2-layer PCBs is selecting the right raw material. The core material is usually made of fiberglass or epoxy resin, providing rigidity and durability to the board.

Laminating the Copper Foil

Once the substrate material is prepared, the copper foil is laminated onto both the top layer and bottom layer. This is done by applying heat and pressure, causing the copper to bond securely to the board.

Drilling Holes

Next, the PCB undergoes the drilling process to create drill holes. These holes are necessary for placing vias, which allow for electrical connections between the top and bottom layers. For 2-layer PCBs, the drill holes are generally smaller and fewer in number compared to more complex multi-layer designs.

Solder Mask and Silk Screening

After drilling, the PCB is coated with a solder mask, a protective layer that helps prevent solder from accidentally bridging connections between traces. The solder mask also provides insulation, ensuring that the copper traces do not short-circuit when the components are soldered onto the board.

Silk screening is then applied to mark the locations of components on the PCB, making assembly easier for manufacturers.

Etching

The etching process removes excess copper from the board, leaving only the copper traces that form the circuit. This is a highly precise step, as any inaccuracies can lead to faulty connections.

Final Testing and Quality Control

Once the board is fully assembled, it goes through a final testing phase to check for short circuits, continuity issues, and other defects. Any issues found during this phase are corrected, ensuring that the 2-layer PCB meets the required standards for performance.

There are several types of PCBs, each designed for specific needs. Understanding the differences can help you determine when to use a 2-layer PCB and how it compares to other types of PCBs:

Single Layer PCB

A single layer PCB (or single sided PCB) features just one layer of copper foil on one side of the board. It is the simplest type of PCB, typically used in low-complexity applications like LED lights, basic controllers, and simple electronics. While single sided PCBs are cost-effective, they are limited in their ability to handle complex circuits compared to multi-layer or 2-layer PCBs.

Double Sided PCB

A double sided board is similar to a 2-layer PCB, but the difference lies in the copper layers. In a double-sided board, the copper layers are on both the top layer and bottom layer, allowing components to be placed on both sides of the board. These PCBs are commonly used in more complex devices requiring a greater number of connections.

Multi-Layer PCB

A multi-layer PCB has more than two layers, typically three to ten layers of copper traces. These types of PCBs are used in more advanced applications like computers, telecommunications equipment, and medical devices, where there is a need for higher-density circuits and greater signal integrity.

Rigid Flex PCB

Rigid flex PCBs combine the properties of both rigid and flexible PCBs. These boards can be bent to fit unique spaces, making them ideal for applications like wearable devices and medical equipment.

2-layer PCBs are versatile and can be used in a wide range of applications, including:

Consumer Electronics: From televisions to gaming consoles, 2-layer PCBs are used in a variety of consumer devices.

Automotive Electronics: Simple control systems in vehicles can benefit from the compact design of 2-layer PCBs.

Industrial Equipment: Many industrial devices and machinery use 2-layer PCBs for basic control functions and connections.

There are several advantages to using 2-layer PCBs, including:

Cost-Effective: 2-layer PCBs are more affordable to produce compared to multi-layer designs, making them ideal for cost-sensitive projects.

Simple Design: The relatively straightforward design of 2-layer PCBs makes them easier to manufacture and assemble, reducing production time.

Effective for Medium Complexity Circuits: For circuits that don’t require excessive routing or complexity, 2-layer PCBs offer a good balance of performance and cost.

A 2-layer PCB is an excellent choice for a variety of applications, providing a balance of affordability, functionality, and ease of production. With two copper layers, it can handle moderate circuit complexity and is commonly used in consumer electronics, automotive, and industrial applications. By understanding the top and bottom layers, the layer of copper, and the production process, manufacturers can create reliable and efficient circuits that meet their design needs.

If you are considering the production of 2-layer PCBs, be sure to work with a trusted manufacturer that has experience in solder mask application, copper foil etching, and quality control to ensure the highest standards of performance.

What is the main difference between a single layer and a 2-layer PCB?

A single layer PCB has only one copper layer, while a 2-layer PCB has copper layers on both the top and bottom, allowing for more complex circuit designs.

Can a 2-layer PCB be used for high-frequency applications?

While 2-layer PCBs are suitable for many applications, they may not perform as well in high-frequency circuits compared to multi-layer PCBs, which offer better signal integrity.

What types of raw materials are used for 2-layer PCBs?

2-layer PCBs are typically made using fiberglass or epoxy resin as the base material, with copper foil laminated onto both the top and bottom layers.

What is the advantage of using a solder mask on a PCB?

A solder mask helps to protect the copper traces from accidental solder bridges, reduces the risk of short circuits, and improves the overall durability of the PCB.