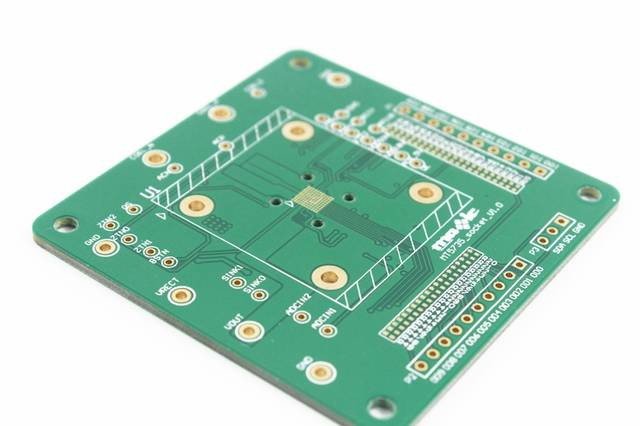

HDI is not a material itself, but rather a technology used in the manufacturing of printed circuit boards (PCBs) to achieve higher density and complexity. HDI technology enables the creation of smaller and more complex circuits with higher density and improved performance. The specific materials used in HDI PCB manufacturing will depend on the requirements of the application, including the electrical and thermal properties, the number of layers, and the size and density of the components. Common materials used in HDI PCB manufacturing include copper foil, resin, core materials such as FR-4 or polyimide, prepreg, and vias.

The choice of materials for HDI PCB (Printed Circuit Board) can have a significant impact on the performance, reliability, and cost of the final product. Some of the most common materials used in HDI PCB include:

1.Copper foil: Copper is the primary conductor material used in PCB manufacturing due to its excellent electrical and thermal properties. HDI PCBs use thinner copper foils to create more intricate and dense traces.

2.Resin: Resin is the primary insulating material used in PCB manufacturing. HDI PCBs use resin materials with higher glass transition temperature (Tg) values to withstand higher temperatures during assembly and operation.

3.Core materials: The core material provides the base layer for the PCB and is made of a non-conductive material, such as FR-4 or polyimide. HDI PCBs use thinner core materials to reduce the overall thickness of the board and to enable more layers.

4.Prepreg: Prepreg is an insulating material that is used to bond the different layers of the PCB together. HDI PCBs use thinner prepreg materials to reduce the overall thickness of the board and to enable more layers.

5.Vias: Vias are small holes drilled into the PCB to provide electrical connections between different layers. HDI PCBs use smaller vias to enable more interconnections within a smaller surface area.

The specific materials used in HDI PCB manufacturing will depend on the requirements of the application, including the electrical and thermal properties, the number of layers, and the size and density of the components. The choice of materials will also impact the cost of the final product, with higher performance materials typically being more expensive.

Get more knowledge about What material is HDI please refer to rigaopcb:https://www.rigaopcb.com/