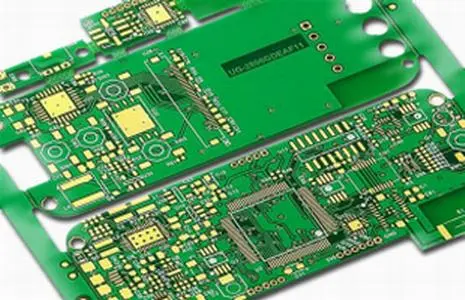

It is reliable and experienced in producing high-quality PCBs. A HDI PCB is a complex circuit board with multiple layers, high-density interconnections, and microvias, making it crucial to find a manufacturer who can produce them with accuracy and precision.Here are 10 Tips for Choosing the Right HDI PCB Manufacturer:

1.Look for Experience and Expertise

Choosing a manufacturer with extensive experience in manufacturing HDI PCBs will ensure that your circuit boards are made to the highest quality standards. Look for a manufacturer that has been in the industry for years and has worked with a variety of clients and industries.

2.Evaluate the Company's Technology

Be sure to assess the manufacturing process and the technology used by the manufacturer. HDI PCBs require advanced manufacturing techniques, such as laser drilling, sequential lamination, and microvias, to achieve the high-density interconnects required.

3.Review the Manufacturing Facility

Ensure the manufacturing facility is clean, well-organized, and equipped with the latest technology and equipment. A reliable manufacturer should be able to provide a facility tour or detailed photos of their production line upon request.

4.Check Quality Assurance Techniques

Look for a manufacturer that is ISO certified and employs rigorous quality control techniques throughout the manufacturing process. Quality assurance measures should be in place at every stage of production to ensure that the finished product meets your specifications.

5.Assess the Design Capabilities

Make sure the manufacturer can handle your specific design requirements efficiently and effectively. The manufacturer should be able to provide design assistance if needed, as well as offer services for design verification and testing.

6.Consider the Materials Used

Ensure that the manufacturer uses high-quality materials that meet the necessary standards for your application. High-density interconnects require materials with excellent thermal conductivity, dielectric properties, and electrical insulation.

7.Evaluate the Lead Times

Check the manufacturer's lead times to ensure that they can meet your project deadlines. Reliable manufacturers should be able to provide accurate lead times upfront and stick to them.

8.Look for Competitive Pricing

Compare pricing from multiple manufacturers to ensure that you are getting a fair and competitive price for your HDI PCBs. However, don't compromise quality for cost savings.

9.Check for Customization

Discuss your requirements with the manufacturer and ensure that they can offer customized solutions to meet your specific needs. They should be able to work closely with you to optimize the design and functionality of your PCB.

10.Read Customer Reviews and Testimonials

Finally, look for customer reviews and testimonials to evaluate the manufacturer's reputation and customer satisfaction. This will give you a good idea of the manufacturer's track record and their ability to meet the needs of their clients.

Get more information about Tips for Choosing the Right HDI PCB Manufacturer please refer to Rigaopcb:https://www.rigaopcb.com/