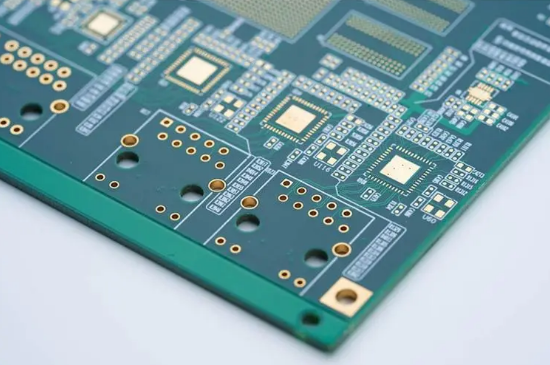

HDI PCB design refers to the use of advanced technology to increase the density of electronic components in a PCB. This design allows for a higher number of components to be placed on a smaller surface area, making it ideal for devices with limited space. Here is a beginner's guide to HDI PCB design:

1.Understand the Benefits: HDI PCBs offer several advantages, including reduced size and weight, improved performance, and a higher level of reliability. These boards are best suited for electronic devices that require high-speed data transfer rates, low power consumption, and complex configurations.

2.Choose the Right Materials: The materials used for HDI PCBs should be high quality and able to handle the high density of components. Materials commonly used in HDI PCBs include FR-4, polyimide, and Rogers. The choice of materials should be based on the specific requirements of the project.

3.Optimize the Layout: The layout of the PCB is critical in HDI design. The location of each component should be carefully planned to ensure the shortest possible connections and minimal interference between components. This can be achieved by using advanced design software that can automatically optimize the layout.

4.Use Advanced Manufacturing Techniques: HDI PCBs require advanced manufacturing techniques such as laser drilling, via-in-pad, and microvias. These techniques allow for the creation of smaller and more complex boards, which is essential for high-density designs.

5.Test and Validate: Before production, it is important to thoroughly test and validate the design of the HDI PCB. This includes electrical testing, thermal testing, and mechanical testing. This ensures that the PCB meets the required specifications for the project.

In conclusion, HDI PCB design is a complex process that requires advanced technology, careful planning, and thorough testing. By following these steps, beginners can create high-performance PCBs that are ideal for electronic devices with limited space.

Get more knowledge about HDI PCB Design please refer to RigaoPCB:https://www.rigaopcb.com/