As electronic devices continue to evolve, the importance of Compact Printed Circuit Boards (PCBs) has grown immensely. This article seeks to navigate you through the essential details of multilayer PCB design guidelines.

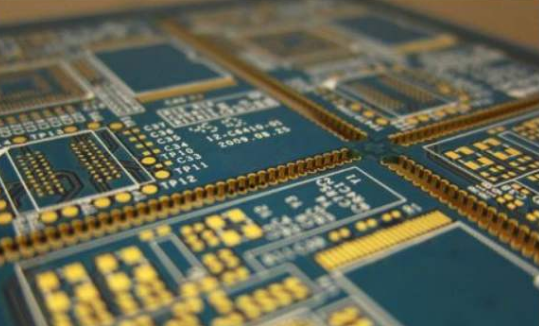

Multilayer Printed Circuit Boards, often abbreviated as PCBs, represent a sophisticated type of electronic circuits. Their principal characteristic rests in the fact that they contain multiple layers of conductive copper pathways or 'tracks'. What sets these apart is that each of these conductive layers is sequentially separated by layers functioning as insulators. The primary function of this design is to provide each conductive layer with a specified path while preventing any cross-communication or electrical interference between them.

Emphasizing their compactness, the space occupied by these multilayer PCBs is surprisingly small, thus exemplifying the amazing efficiencies of modern engineering design. Their compact design is strategic, aimed at facilitating the execution of extensive and rather complex electrical tasks. Regardless of their miniature size, they are capable of satisfying the necessities of even the most intricate and demanding electronic applications.

Invented to enable larger electronic capabilities within ever-shrinking devices, multilayer PCBs showcase a necessary evolution in electronic circuit board design. They are not just a representation of cutting-edge technology, but also a perfect testament to the smart usage of limited spatial allocations to accommodate complex functionalities. Their role is undeniable in the contemporary world where electronic devices are continuously shrinking in size while growing in capabilities.

Printed circuit boards (PCBs) are an indispensable part of today's electronic devices, ranging from simple household appliances to complex medical equipment and high-tech spacecraft. These boards are made up of thin layers of conductive materials, laminated together to form a single board. PCBs are designed to contain electrical components and form a complete circuit, allowing electronic devices to function properly.

The high-density and performance capabilities of PCBs are crucial in advanced electronics. They enable the use of a large number of components and connections in a compact space, making them ideal for devices requiring a high degree of miniaturization, such as smartphones, laptops, and wearables.

Moreover, PCBs ensure reliable and efficient performance by providing a stable platform for electronic components. They offer excellent electrical insulation, reducing the risk of electrical noise, and enable precise and consistent signal transmission, ensuring that electronic devices function smoothly and accurately.

In summary, PCBs are the backbone of modern electronics, enabling the creation of sophisticated devices that have become an integral part of our daily lives.

PCB design, or printed circuit board design, is a process that involves creating a circuit that can fit seamlessly into the board without any hindrance. It's an intricate and detailed process that requires a deep understanding of electrical engineering, as well as the ability to think creatively to maximize efficiency.

During the design process, each component of the circuit must be meticulously arranged and positioned in a way that not only fits on the board, but also maximizes the circuit's overall performance. This requires a keen eye for detail and a thorough understanding of the interplay between each component.

It's often said that PCB design is like a game of chess, as each move must be carefully considered and planned out to ensure success. This is because even a small mistake in the placement of a single component can negatively impact the entire circuit's performance.

Ultimately, a successful PCB design requires a combination of technical expertise, creativity, and attention to detail. When done correctly, it can result in a highly efficient and reliable circuit that can be used in a variety of electronic devices.

Elements of PCB Design

The process of designing an electronic circuit involves several crucial elements. One of the primary steps is schematic capture, which involves creating a visual representation of the circuit using symbols and diagrams. The next step is component placement, where the designer decides where each component should be located on the circuit board. Once the placement is determined, the routing step involves connecting the components in the most efficient way possible. Finally, the designer prepares the gerber file, which is necessary for manufacturing the circuit board.

The key to writing in Plain English is understanding your audience and their needs. Different people require different information, so it's essential to present it in a logical and clear way. Important information should be mentioned at the beginning, and sentences should be kept short, with only necessary information included. Long, wordy sentences can be confusing and should be avoided. The text should be direct, concise, and easy to read. Use everyday language rather than acronyms, jargon, or legal terms. Use verbs instead of nouns to make the text more clear, and use the active voice to make it more engaging. Remember not to change the meaning of the text or add or remove any important information.ing, ensuring a high-quality final product.

This aspect is vital to minimize crosstalk and maintain signal integrity. Calculators are available for precise determination of trace widths.

Holes for mounting and vias for connections make up the skeletal structure. The holes should be accurately sized, and vias must be optimally placed to avoid congestion.

This stage requires great skill to organize active and passive components, considering heat generation and signal interferences.

It involves strategizing the heat dissipation to avoid any performance inconsistency due to thermal stress or overheating.

H4: Use of Heat Sinks & Vents

These lower thermal hotspots. Vents allow airflow, while heat sinks absorb and disperse heat.

H4: Thermal via Allocation

Vias, specifically designed to conduct heat away from the parts generating it, are allocated around the board.

Multiple software like Altium Designer, Cadence, and KiCad extend advanced features for designing multilayer PCBs.

Common pitfalls include improper track routing, insufficient spacing, poor thermal management, and inefficient layer stack design.

Multilayer PCBs are challenging yet inevitable entities in the electronics world. By cautiously following the mentioned guidelines while designing, one can craft an efficient and reliable multilayer PCB.

What is a multilayer PCB?

A multilayer Printed Circuit Board (PCB) is designed with several layers of conductor tracks, which are each isolated by layers of insulating material. This design allows the creation of complex electronic circuits.

2.What is the importance of the stackup design in multilayer PCBs?

A balanced and symmetrical stackup ensures a high-quality final product by minimizing issues such as warping or twisting.

3.What role do vias play in thermal management of multilayer PCBs?

Thermo-conductive vias help dissipate heat from the parts that generate it, aiding in overall thermal management.

4.What are some common mistakes in multilayer PCB design?

Common mistakes include improper track routing, insufficient spacing, poor thermal management, and inefficient layer stack designs.

5.What software can I use for designing multilayer PCBs?

Some popular software includes Altium Designer, Cadence, and KiCad, all providing advanced features for designing multilayer PCBs.